1 / 3

1 / 3Automated wire bending

Hardware Price:

ROI

3 - 6

months

availability for Production

24/7

Max. velocity

0.2

meters per second

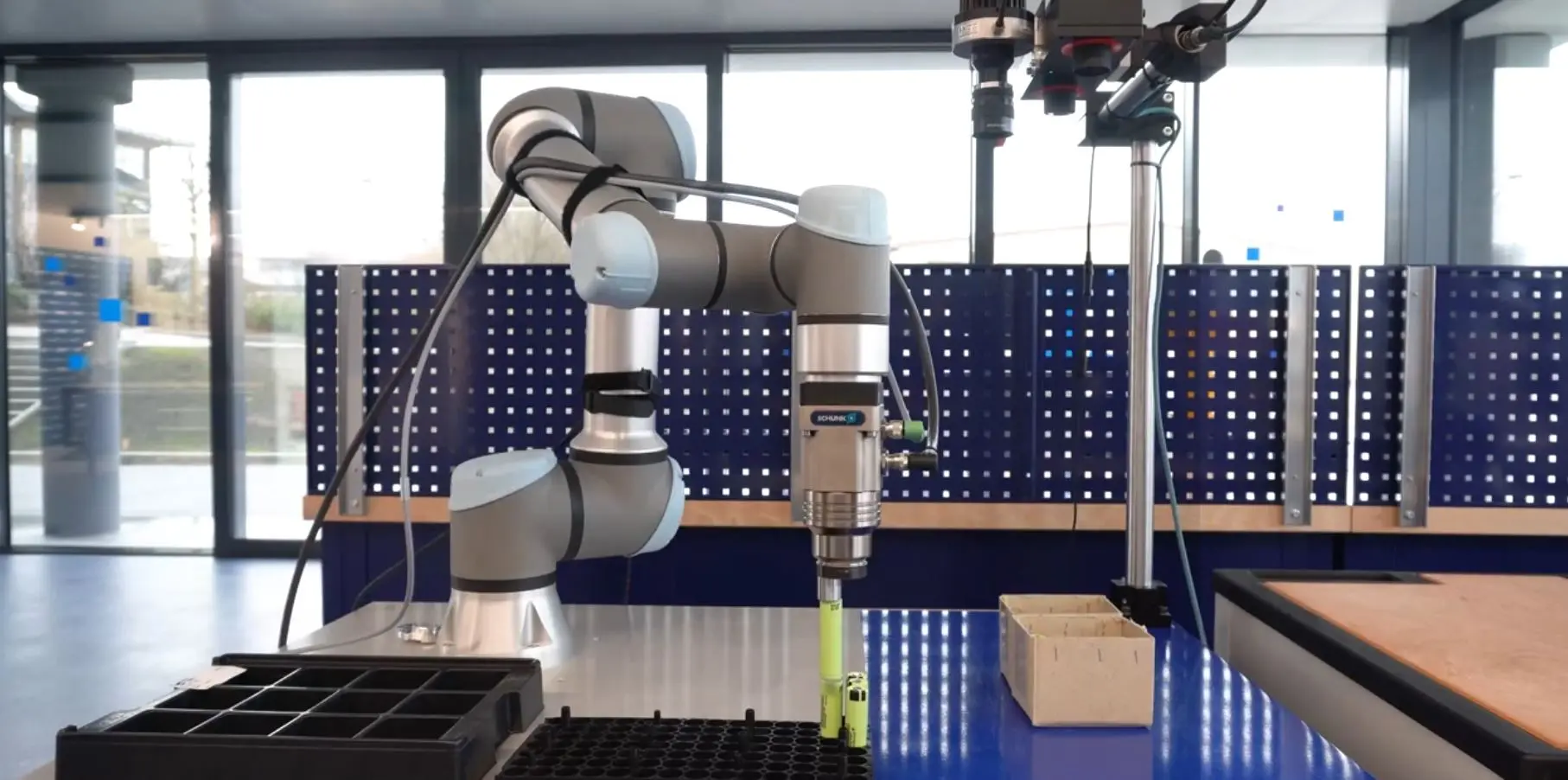

Automated Wire Handling with robolink DP: Efficiency in Automotive Manufacturing

In the automotive supplier industry, precision and reliability are critical for maintaining production efficiency. proseat GmbH addresses this need by utilizing the robolink DP, a 5-axis pick-and-place robot, to automate the handling of bent wires. This system operates independently within a grid enclosure, ensuring around-the-clock production with minimal manual intervention, while significantly improving workplace safety.

What is the Application?

The robolink DP robot automates wire handling in bending machines, removing bent wires and placing them onto carrier systems—all while functioning seamlessly during continuous production cycles.

What are the Advantages of the Solution?

24/7 Operation: Maximizes productivity with autonomous processes.

Improved Safety: Eliminates risks of personal injury during wire handling.

Reduced Labor: Manual input is limited to refilling wires and emptying carriers.

What are the Advantages of the Robot?

The robolink DP provides key benefits for automation:

High Precision: Ensures consistent positioning of bent parts.

Compact Design: Fits efficiently into existing production setups.

Cost Effectiveness: Designed for durable and economical operations.

Modernizing Wire Bending with Automation

By integrating the robolink DP, proseat GmbH has streamlined wire bending workflows, achieving continuous production, enhanced safety, and reduced labor requirements. This robotic solution offers a scalable and efficient approach to automating repetitive tasks in industrial environments.

2 Components