1 / 3

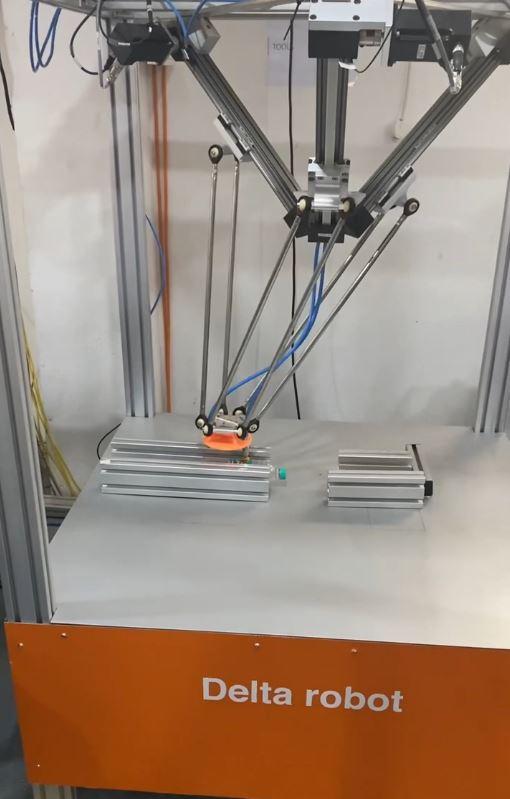

1 / 3Customer Test - Delta robot sorts plastic bottles from waste

Test before Invest

Hardware Price:

DOF

3

Max. payload

5

kg

Precision

+- 0,5

mm

Efficient Plastic Bottle Sorting with Suction Pad and High-Speed Robot

As part of a waste separation system, the customer sought a solution to automate the handling of plastic bottles. In this application test, a robot equipped with a suction pad successfully demonstrated its ability to pick bottles and place them securely into a device. The test focused on the suction pad's functionality and the robot's operational speed, ensuring reliable bottle pickup and rapid movement. This automated system highlights the role of robotics in streamlining sorting tasks in recycling and waste management.

What is the Application?

The robot automates the sorting and placement of plastic bottles within waste separation workflows, optimizing tasks for recycling centers and waste-processing environments.

What are the Advantages of the Solution?

Reliable Suction: The suction pad ensures secure gripping of bottles, regardless of shape or material.

High Speed: Fast robotic movements increase throughput in waste sorting.

Consistent Accuracy: Precise placement reduces errors and improves efficiency.

What are the Advantages of the Robot?

The robot excels in sorting operations with:

Adaptable Design: Handles diverse bottle sizes and materials.

Swift Performance: Accelerates repetitive pick-and-place tasks.

Enhanced Reliability: Consistent functionality under intensive usage.

Optimizing Waste Sorting with Robotic Automation

This test demonstrates how a robot with suction pad technology can efficiently handle plastic bottles, enabling faster and more reliable sorting processes. Ideal for waste separation systems, this solution enhances productivity, reduces manual labor, and ensures accurate performance in recycling operations.

2 Components