1 / 3

1 / 3Assembly of plastic lids with igus gantry robots

Hardware Price:

DOF

2

Working space

800x500

mm

Repeatability

0.5

mm

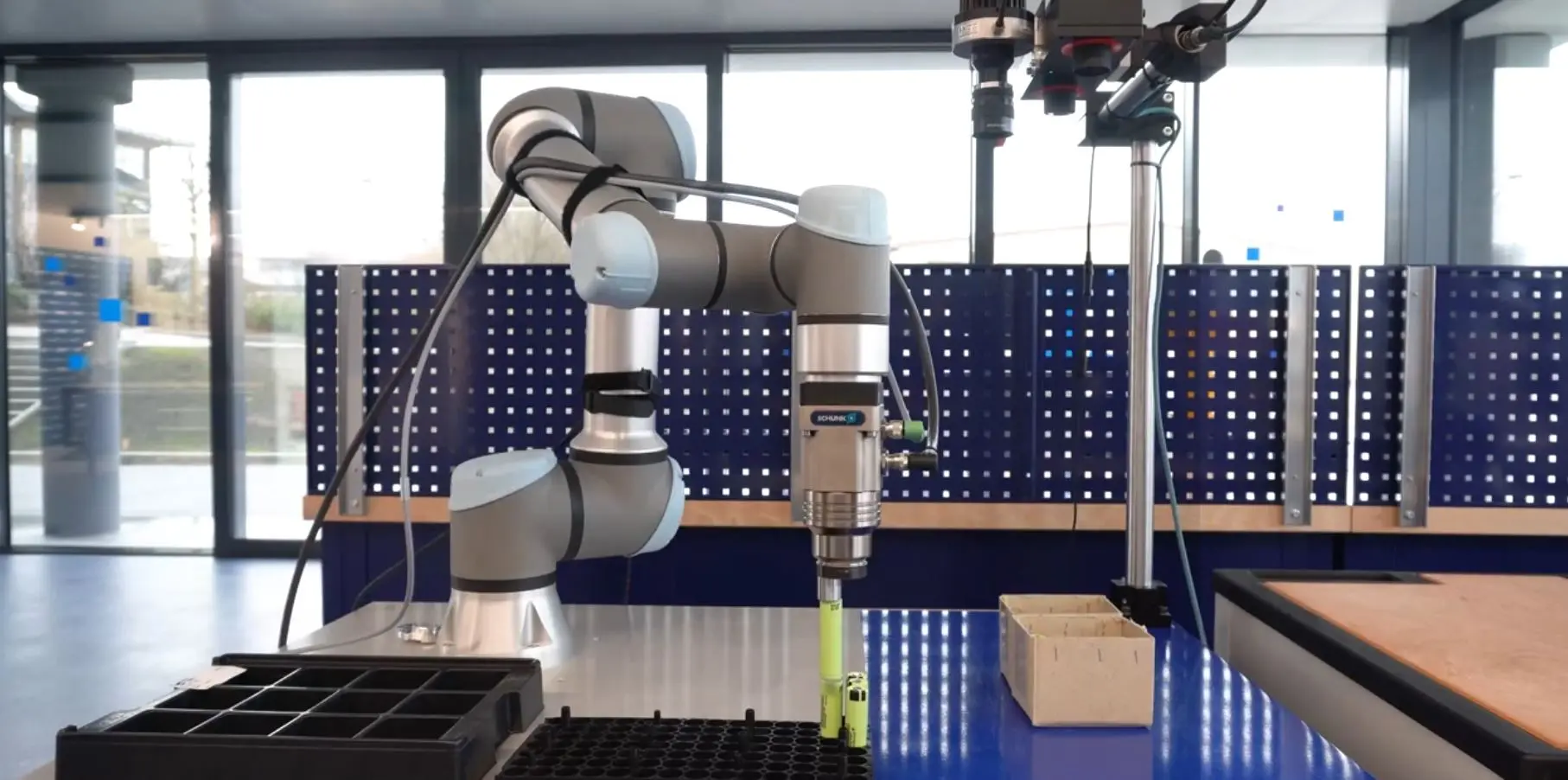

Automated Plastic Lid Placement with igus Linear Robot: Precision and Efficiency

This technical demonstration highlights the operation of an igus linear robot, showcasing its ability to handle plastic lids with high precision and reliability. The process begins with the robot securely gripping a plastic lid using advanced gripping technology. It then moves to the next step, where the lid is carefully mounted onto the container by clipping it firmly into place. The seamless execution of these tasks underscores the efficiency and adaptability of the igus linear robot in industrial automation.

What is the Application?

The system automates plastic lid placement onto containers, ensuring secure and accurate fitting in production environments requiring repetitive, high-precision tasks.

What are the Advantages of the Solution?

High Accuracy: Ensures perfectly clipped lids with precise positioning.

Improved Workflow Efficiency: Automates time-consuming manual processes.

Consistency: Maintains reliable results in high-demand operations.

What are the Advantages of the Robot?

The igus linear robot provides key benefits:

Precision Handling: Advanced gripping technology prevents mishandling.

Flexible Integration: Easily adapts to various container and lid designs.

Speed and Reliability: Performs tasks quickly without compromising accuracy.

Streamlining Manufacturing with igus Linear Robots

The precise and efficient handling demonstrated by the igus linear robot showcases its significance in modern automation. By ensuring accuracy and speeding up repetitive tasks, this solution offers manufacturers a cost-effective and scalable way to optimize production workflows in industrial applications.

2 Components